Cold transfer is a modern method of applying metallic particles to a substrate to add metallic effects and value to the final product. Cold transfer is a common technology in the offset printing industry.

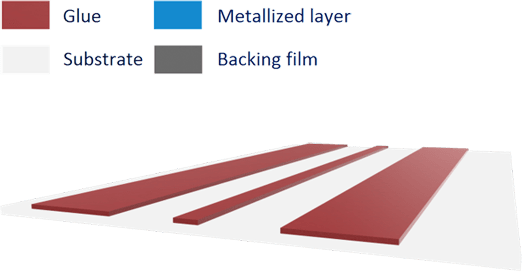

Using a standard offset plate, an image is printed onto a substrate by the use of a tacky adhesive. Foil spools from an unwind and are nipped to a substrate. The aluminum particles from the cold foil layer are released from the polyester film and transferred to the substrate by the tack of the glue. An image with a bright surface is created on the sheet. Foil that does not adhere to the adhesive remains on the 12um film, and waste is directed to a rewind spool or a shredder (Vinfoil Infigo systems).

Because the adhesive is applied like a conventional ink, no expensive stamping die has to be created. Once printed, the surface of cold foil images may be overprinted and varnished.

With both hot foil stamping and cold transfer technology being eco-friendly printing techniques, why should you choose cold transfer? Well, let us explain:

Cold transfer can be done inline, at a maximum speed of 20.000 sheets per hour. Compared to the hot foil stamping process, where it is impossible to do it inline and where the maximum speed only is 4.500 sheets per hour, cold transfer technology is much more efficient.

By using standard offset plates, which can be created fast, it is also less expensive than hot foil stamping where you need customized and expensive dies to start the process.

So, cold transfer technology is great in optimizing your business and profit simultaneously.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |