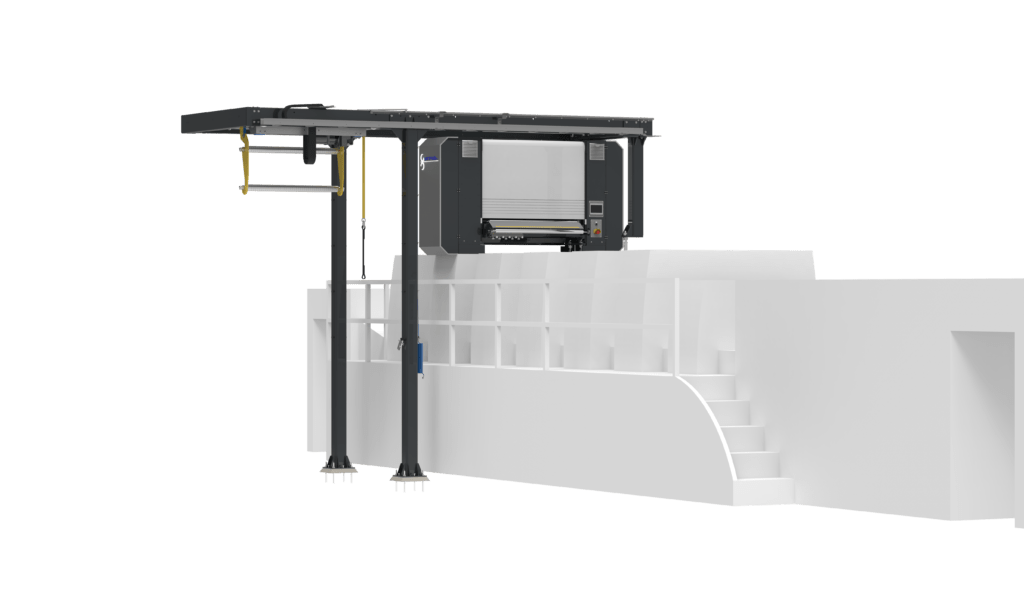

Direct Foil Drives (DFD) & Direct Foil Brake (DFB)

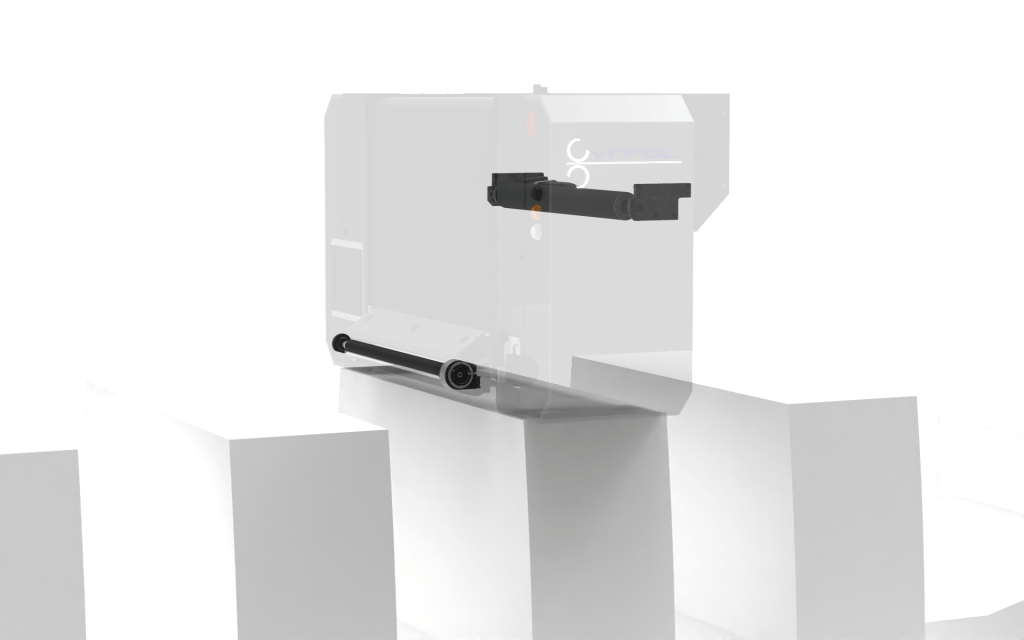

The Micro SF110UFC is outfitted with a DFD and a DFB roller. With the DFD roller, the film web speed is controlled to match the exact speed of the printing press. The DFB roller is placed just before rewinding. This ensures perfect tension of the film web and optimal rewinding. Due to the DFD and DFB rollers, the cylinder gap has no influence on the film loop and tension, thus improving the print quality